Print This Page

Print This Page

Email This Page

Email This PageAccessory Fasteners for Metal Building Construction

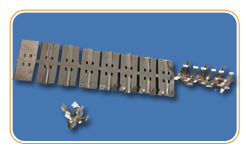

(click on thumbnail to enlarge)

Metal Tech Company, Inc. contracts with customers in the construction industry to fabricate custom accessory fasteners used as construction components for metal structural elements. Utilizing a state of the art 60 ton capacity straight side press with automatic coil feeding, progressive stamping of 0.039” thick G90 galvanized steel is carried out to achieve the specified profiles. Multiple manufacturing processes, including stamping, punching, and forming, are employed during fabrication while holding a tight tolerance of ± 0.003” throughout. Various sized components are manufactured and combined with a form press assembly process. Overall finished dimensions include a length ranging from 4.250” to 10.030” and a width range of 5.150” to 8.000". The finished part is processed with a “chem treat dry” surface treatment for corrosion inhibition.

For this project, over 50,000 fasteners are produced monthly and shipped throughout the United States. This process conforms to federal standards and requirements with a rigorous internal quality control inspection process. The high volume production capabilities of Metal Tech yield high accuracy and repeatability over long term production. Metal Tech strives to exceed the expectations of customers across a wide spectrum of industries. For more information about this accessory fasteners fabrication or the other precision metal manufacturing services available from the company, please see the table below or contact Metal Tech directly.

Accessory Fastener Project Highlights

- Product Name

- Accessory Fasteners

- Product Description

- These accessory fasteners are used as a component for metal building construction.

- Capabilities Applied/Processes

-

- Primary:

Progressive Stamping- Stamped, punched and formed

- Automatic coil feeding system

- Secondary:

Form-Press Assembly- Two-Piece Assembly

- Primary:

- Equipment Used to Manufacture Part

- 60 ton capacity straight side press

- Overall Part Dimensions

-

- Length: 4.250" - 10.030"

- Width: 5.150" - 8.000"

- Tightest Tolerances

- ± 0.003"

- Material Used

- G90 Galvanized Steel

- Thickness: 0.039"

- Material Finish

- Chem treat dry

- In Process Testing/Inspection Performed

- Continuous quality control inspection

- Industry for Use

- Construction

- Volume

- 50,000+

- Delivery/Turnaround Time

- Monthly

- Delivery Location

- National

- Standards Met

- Customer Specifications, 2D Drawing, CAD Capability

sales@metaltechcompany.com

sales@metaltechcompany.com